Coating Service Description

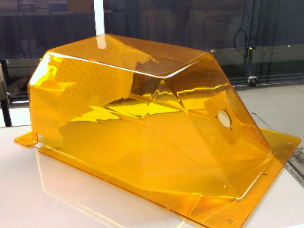

SciCron Technologies offers custom coating services for molded, formed, and fabricated plastic parts. Customer-supplied parts can be coated with any of SciCron Technologies performance enhancing static dissipative, anti-static, or mar resistant coatings. These high quality clear coatings are applied utilizing a variety of techniques in a Class 100 clean room setting. A combination of precise application control, coatings formulated and made by SciCron Technologies, and state-of-the art processing equipment results in coated surfaces that are uniform, consistent, and highly functional. The coatings can be applied to parts made from many different plastic types in a wide array of sizes, shapes, and complexity.

Part Description

SciCron Technologies coatings can be applied to clear and opaque acrylic, polycarbonate, PVC, PETG, polyurethane, polyester, and several other plastic types including multiwall polycarbonate. Parts that have been injection molded, vacuum formed, compression molded, extruded, machined, or otherwise fabricated, are suitable for coating. Part coating capability ranges from coin size to large fabricated parts.

Coating Properties

All SciCron Technologies coatings are custom formulated to provide the required properties and to accommodate the plastic being coated. These proprietary coatings are cured onto the parts in a chemical cross-linking process. This results in excellent adhesion, chemical resistance, and durability. The following is a general description of the properties of SciCron Technologies most frequently specified coatings.

- C-300™ Static Dissipative

- The C-300 coating is both static dissipative and anti-static meaning that it resists charge generation under all circumstances and cannot generate a charge when properly grounded. The C-300 coating chemistry employs superior permanent static control technology that is completely independent of ambient humidity. C-300 is a clear coating that is more abrasion resistant than most plastic substrates, thereby providing added mar resistance to the coated surfaces. It also has excellent chemical resistance, which makes the coated surfaces easy to clean.

- Mar-Con® 600 Abrasion Resistant

- The Mar-Con coating is a clear, hard, durable, cured coating. Mar-Con 600 coated surfaces are considerably more abrasion resistant than plastic substrate surfaces, and they provide excellent resistance to a wide variety of chemicals, cleaners and solvents. This combination of properties results in enhanced resistance to hazing, marring, abrasion, and scratching from handling, cleaning and defacement efforts. In addition, the Mar-Con 600 hard coat type coating is water clear making it suitable for many optical quality applications.

- AF-200™ Permanent Anti-Fog

- The AF-200 Anti-Fog coating is a clear hydrophilic surface treatment that causes moisture from the air to spread in an even film over the plastic surface without forming droplets. Consequently, the surface remains free of fog, even under very humid conditions that would normally cause fogging of the surface. This cured permanent coating eliminates the need for temporary anti-fog sprays, wipes, and solutions.

- AG-400™ Anti-Glare

- AG-400 is a primer free, permanent anti-glare coating applied in-house to plastic substrates. This coating reduces reflected glare from light sources, thereby enabling a clearer view of the underlying printing, panel, or artwork. This allows the underlying display to be read quickly, comfortably, and clearly. Anti-glarecoated plastics can be used wherever surface glare is a concern.

- AGM-700™ Anti-Glare, Anti-Microbial

- AGM-700 is essentially AG-400™ enhanced with our excellent anti-microbial properties that will not leech, cause discoloration, or affect the final product. The anti-microbial component kills microbes upon contact thereby reducing transmission of pathogens from the coated surface. Ideal applications include instrument gauges, artwork, hospital digital displays, and other transparent plastic surfaces where reflected glare, finger prints, and pathogen transmission is an issue.

Coating Service Requests for Quotation

SciCron Technologies is a high quality specialty coating company with an excellent reputation for solving customers’ coating challenges – we welcome customer inquires. Customers with parts requiring coating can contact the SciCron Technologies Customer Service Department at our Amarillo, Texas facility for a quotation. Submittal of material type, sample part, drawing, or sketch with the request will help facilitate preparation of the quotation. Email inquiries can be sent to info@sctech.com.

The information and statements contained herein are believed to be accurate, however, users should perform their own testing and verification to determine the durability, applicability and suitability of the products for their own purposes. NOTHING CONTAINED HEREIN SHALL BE CONSTRUED AS A REPRESENTATION OR WARRANTY OF ANY KIND, EXPRESS OR IMPLIED. IMPLIED WARRANTIES OF MERCHANABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY EXCLUDED. All sales are subject to SciCron’s standard terms and conditions of sale.